As industrial heaters, dryers, and ovens age, questions about their performance normally arise. Are they still generating sufficient heat? Are they still performing efficiently? Is there a better, more cost-effective way for them to produce more heat? Does the oven need to get replaced or refurbished?

Of course, industrial ovens lose their efficiency once they go past their useful life. Product quality compromise, production delay, and raised heating cost all result from the inefficiency of these types of equipment. However, users should consider whether upgrading the chamber with supplemental heaters or refurbishing it with a retrofit, would provide significant cost savings and resolve underperformance issues before replacing the oven entirely.

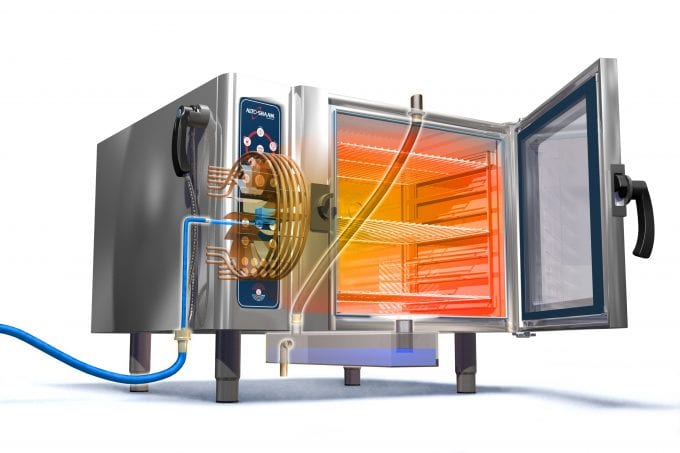

One must consider several variables before deciding to replace or refurbish an industrial oven, whether it’s convection or infrared; gas or electric. Learn more below.

Industrial Oven Conditions

There are unavoidable situations where an industrial chamber suffers wear and tear, especially from years of use. Before visiting the websites of manufacturing and repair companies like pqovens.com and making the decision of whether to have your equipment repaired or replaced, address the following conditions first.

- Current Oven Condition – Is the equipment sound mechanically? Most chambers consist of a structural steel framework and sheet metal. If both sheet metal and structural steel framework are not rusty, perforated, deteriorated, or unstable mechanically, which means that they’re sound, the oven could still be refurbished.

- Ductwork Condition – Check the condition of the ductwork if the industrial oven has a convection design. It’s most likely still distributing the heat all throughout the oven as designed if the ductwork isn’t perforated with multiple holes, and still in good condition. Sheet metal analysis can help in checking the ductwork.

- Conditions Of Mechanical Systems – If the recirculating blower is well-maintained and still fully operational or the exhaust blower is still in sound condition, a refurbish will do.

- Condition Of Those Elements That Tie Into The Oven’s Mechanical Systems – Together with the heating system (whether electric or gas), the elements that tie into the equipment’s mechanical systems should also undergo evaluation.

You should replace the industrial oven if none of the factors above are in good shape. However, if some of them are still in good condition, you’ll often find that refurbishing the equipment is the best solution. And if all of the factors above are satisfactory, yet the machine seems to be producing not enough heat, it will likely need some supplemental heaters reinforcement.

That said, in the entire course of having the industrial oven, the two most significant repair changes that you’re going to make are upgrading and retrofitting. What are these processes, and how vital are these repairs? Read on to learn more.

Retrofitting, What Is It?

The process of retrofitting will add new technologies or features to your existing industrial chamber. Hence, when retrofitting the current machine you have, the equipment becomes more effective than before. It, of course, takes away the need of having to purchase a brand new one.

Generally, retrofitting is done for specific purposes. For example, you’re doing so to increase the oven’s maximum temperature. Retrofitting can essentially solve the problem if ever you feel like your current machine isn’t meeting the needs or standards of your business.

Industrial Oven Upgrading, What Is It?

Unlike retrofitting, where you’re going to focus on a single area of the industrial oven using parts that are also centered on the oven’s area you wish to upgrade, upgrading concentrates not only on one specific area. Upgrading also improves all the equipment’s necessary parts. Its purpose is to make the whole chamber better both in terms of capacity and function.

What Are The Benefits Of Industrial Oven Repair?

Takes Away The Need To Purchase A New Oven

Obviously, one of the most important benefits of industrial oven repair is the lesser need to purchase a new one.

As already mentioned, the chamber loses its efficiency once it goes beyond its useful life. Hence, affecting product quality, causing the costs to rise, and delaying the production. It, of course, will make your business suffer. When this occurs, you may feel that there’s a need to purchase a new machine. But, as long as the parts are still intact, and some of them are still working, an upgrade or retrofit will suffice.

All you need is to replace the parts to solve the problems that your industrial chamber is currently experiencing. That’s pretty straightforward. Some of the parts that you may have to order are porcelain terminal blocks, heat controls, high-temperature insulation, and heating elements.

Reduces Maintenance Expenses

The cost of upgrading or retrofitting is going to be considerably lower when compared to buying a brand new industrial oven. After all, you only need to spend money on the parts or the components that are going to be replaced.

Also, the performance and efficiency of your existing chamber will improve when you’ve upgraded it. New parts will always be generally better than the older ones. The result, in the long run, is lowered maintenance expenses.

There’s also no need to worry about how you can gain back what you’ve lost from the retrofit or upgrade since the rate of return of doing industrial oven repair will be faster compared to that of buying brand new equipment. In the long run, your business will run better, especially with maintenance costs getting lowered, too.

Other benefits that are in line with costs are better material handling integration with other processes, better new manufacturing data availability, lower transportation and rigging expenses, and improved availability and uptime.

Boosts The Oven’s Performance

If you have the right parts, the oven’s performance will get a boost from the heating elements after the upgrade. You’ll enjoy a better overall performance while being able to keep the original specs of the equipment. Those become possible even without having to buy a new chamber.

Conclusion

In conclusion, better performance, reduced maintenance costs, shorter schedule, and reduced capital cost are the benefits of retrofit, rebuild, or repair of an industrial oven. The overall efficiency of the machine improves, helping your business perform better as well.