Businesses of all sizes buy supplies to keep their day-to-day operations running smoothly. It’s one of the things that comes with running a business; by managing overhead costs like buying supplies, a business can project their profit ahead of time and work within a safe margin.

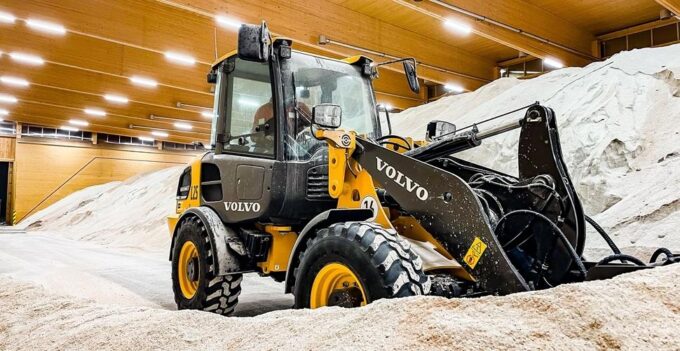

Heavy equipment, however, isn’t like most supply costs. Buying equipment like a bulldozer, excavator, or crane is going to require a specialized seller and to be careful to get the best price for a piece of equipment that will perform as needed and last for a long time.

The decision to buy a new or used heavy machinery depends on your financial situation and the duration you need to work with the equipment. For short-term use, renting one rather than buying is the best option. Remember, the cost of owning heavy equipment includes not only its upfront price but also the costs of maintenance and repair, energy, transportation, insurance, and storage.

Important things to consider when buying heavy equipment

Getting a reputable seller in your local area might be challenging, especially when purchasing used equipment. It’s a specific sort of business, after all. Believe it or not, moving your search online is a good way to see what’s available and what you’ll have to pay for the equipment you need. A company like My Little Salesman, for example, has new and used commercial trucks and semi trailers available, giving you the chance to see what each of those price points look like.

From there, it’s about longevity – finding the part you need with the assurance that it’s going to last and be a staple to your services moving forward. The best way to assure quality is to look for a seller’s inspection report to help you understand the quality they deal with. Also, reading reviews from other buyers can help you make the right decisions. If you are buying straight from the manufacturer, ensure you choose reputable makers of quality machines.

Larger equipment is costly to buy, maintain and operate, but they get the work done faster. Therefore choose equipment that fits on the job site.If you are buying a used machine, ensure that it is under warranty. Heavy equipment has long warranty periods. So, purchasing a piece of equipment without a warranty indicates it has been overused and will not serve you as required. Consider the number of hours the machine has worked.

If it has operated for many hours, it is prone to getting mechanical failures

A piece of used heavy equipment should be serviced regularly and well-maintained. If you notice gaps in in-service history, it is an indication that the equipment is not in good condition. Equally, look for repair-marks and new paint as they affect the durability of the heavy equipment. New parts installed because of an accident affects the longevity of the machine.

Give the equipment a thorough inspection. Check for leaks and damage and if you are unsure, get a professional inspector to assist you. There are many types of brands in the market. Go for well-known and reputable brands known for being durable and reliable. Also, do not buy brands that have been discontinued as it will be difficult to get spare parts like replacement hydraulic cylinders when the equipment needs repairs.

Do not purchase if the seller does not allow you to test drive the equipment. It is a red flag; the equipment is faulty. When test driving, listen to any weird sounds from the machine. Finally, ensure the device has all the required certifications and documents to avoid falling into fraudulent scams.

Signs that your business needs a new machine

With the growth in technology, heavy equipment is changing now and then, upgrading and adding details that increase its performance. Whether in mining, road construction, farming, or structural construction businesses, heavy equipment affects business productivity. Using old, outdated, and faulty machines slows work, is inefficient, and affects the job’s quality.

Increased maintenance costs

If your heavy equipment is using more than is required in maintenance, it is time to upgrade. Spending more on fixing mechanical problems leads to losses in the business. You will be wasting time dealing with constant machine malfunction, which can cost you clients as you will not deliver services as per the schedule. New machines get the work done fast, quickly, and efficiently.

Reduce the number of machinery

It is time to get a new machine that can multitask. This means you have a fewer number of equipment to maintain and also a fewer number of machine operators translating to more profits. Modern equipment is embedded with state-of-the-art technology, allowing them to multi-function, saving time and money in the long run. Newer machines also ensure that the quality of work is not compromised.

Going green

Many clients prefer working with environmentally-friendly equipment. If your machine has high carbon emissions, some customers might shy away from enlisting your services. Upgrade to newer eco-friendly and fuel-efficient heavy equipment to help in the protection of the environment.

Late completion of tasks

Timely completion of tasks is the key to maintain and get more clients. If the slow execution of functions is the heavy equipment, it is time to replace them. Invest in equipment that has cutting-edge technology to ensure the work is done before the deadline.

When to buy or rent heavy equipment

The decision to buy, lease, or rent equipment depends on the duration you intend to use the machine, the geographical region the device will be used in, the amount of capital at your disposal, and the technician’s and operators’ professional level.

You can buy heavy equipment such as excavators, compact track loader and more from Doggett Equipment. You can visit their site and browse the available equipment.

Advantages of buying the equipment

For long-term projects, consider buying your heavy machine because it is a one-time investment. Renting is expensive, especially if your business depends on the device. Buying your machine gives you the freedom to hire experts to operate, upgrade and service it, which increases safety in the field. Also, you will be able to finish projects on time as the equipment is at your disposal.

Disadvantages of buying the equipment

Small businesses and start-ups may not have the necessary facilities to store the equipment. Machines left outside can get damaged easily due to inclement weather. Renting is a better option as the burden of having storage lies with the renting company.

With technology evolving, more advanced machines are flooding the market. It isn’t easy to buy heavy equipment often. With rental companies, you can rent the latest and most advanced device for your project. Similarly, you can rent a piece of kit based on several brands.

Also, any new machine depreciates with usage. This implies that its value goes down with time, and you may have trouble reselling it later. With the rental, you get to minimize the risks that come with owning the machine. You get to conserve capital when you rent, which can be used in growing the business.