One of the first CNC machines started their development in the 1940 and 1950s and relied completely on a common telecommunication data storage known as “perforated paper tape” or “punched tape.” Punched tape technology went out of date pretty fast and transitioned into analog and later into digital computer processing in the 1950s and 60s.

How it Works

Machining, in general, is the way to transform a single piece of material such as a block of plastic and through a controlled material removal process create a finished product (prototype). Similar to other prototype development technologies, 3d printing (FDM), CNC completely relies on digital instructions from a CAM (Computer-Aided Manufacturing) or CAD (Computer-Aided Design) file from Solidworks 3D. The CNC machine interprets the design information as instructions to cut up the prototype parts. The ability to freely program a computer to control machine tools advances productivity by automating all the highly technical and labor-intensive processes. Automated machine tools improve both the accuracy and the speed of the cuts which create the prototype parts – especially when the material is fragile or expensive. That means that every single part of the material needs to saved or used instead of thrown away.

Often machining processes require different add-on parts to make the cuts we want (like different sized drills). CNC machines can combine tools into common cells or units from which the machine can draw. Basic CNC machines can move in only one or two axes while some advanced machines may even move in the x and y-axis, rotationally about one or more axes and longitudinally in the z-axis. These multi-axis machines are even capable of flipping parts over by themselves, allowing you to remove material that is “underneath”. This eliminated the need for workers that have to flip the stock material and allows the machine to cut all sides without the need for manual work. Fully automated cuts are almost always much more accurate than the ones done by manual inputs. However, sometimes finishing prototype work with etching is better done by hand as well as some simple cuts that require special design instruction to program the machine for automation.

Are you looking for a way to reduce your workload and increase your quality? Then look no further and check out ArtMachining if you want CNC machining that is very cost-effective with minimal errors.

Types of CNC Machines

CNC machines usually fall into just two general categories: novel machining technology and conventional machining technology.

1. Conventional Technologies

a) Drills

Drills work by spinning a drill bit and moving the drill around while coming into contact with the stock material.

b) Lathes

Lathes are the complete opposite of drills. Instead of spinning the drill against the material, you spin the block of material against the drill bit. Lathes make contact with the material by laterally moving the cutting tool until it touches the spinning block of material.

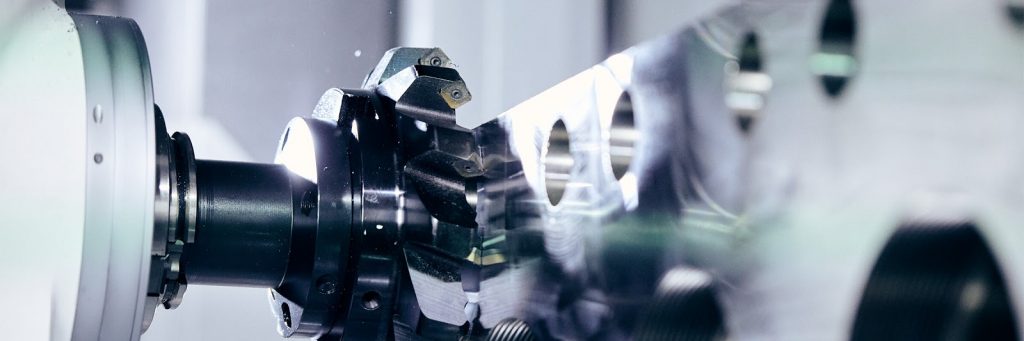

c) Milling Machines

The use of rotary cutting tool bits to remove material from the block.

2. Novel Technologies

a) Electrical or Chemical Machining

Electron Beam Machining, Photochemical Machining, Ultrasonic Machining, and Electrical Beam Machining are all novel technologies that use specialized techniques to cut material.

b) Other Cutting Medium

Oxy-fuel Cutting Machines, Laser Cutting Machines, Water-jet Cutting Machines, and Plasma Cutting Machines are also novel technologies but these use different mediums to cut material.